Creating wellbeing and optimizing energy consumption

Measuring air quality, such as temperature and CO2-levels, benefits both human beings and buildings. It both helps identifying air quality problems – which could have both short and long terms impacts on health – and optimizing the energy consumption.

Cables vs. wireless solutions in installation

A traditional approach to setting up a modern building automation system with measurement sensors translates into hiding kilometers of cables within the structures of a building. An approach that usually takes place during the construction of a building.

As regards old buildings, renovating and updating building automation by installing wired sensors and the corresponding instrumentation cables, would require tearing down structures. This, of course, means costs and inconvenience to the inhabitants of the building.

Wireless M-Bus beta phase is over

Over the past 10 years, wireless measuring technologies have become reliant. Research and development, as well as Fidelix real-life installation of nearly 1 000 000 wireless sensors in multiple locations in Sweden, has helped us finetune our technology as well as improve the software.

We are happy to announce we are well past the beta testing period.

Wireless technology is expensive?

Let us first discuss the cost factor. Yes, in many cases wireless technology is more expensive than the traditional wired technology. Sensors that connect to cables are less expensive than the wireless alternatives.

Instrumentation cables, however, costs around €2 per meter. Given that a building automation requires kilometers of cables, the actual costs of cabling work end up forming a significant amount of a construction budget. This is where the cost of wired devices exceeds the costs of wireless devices.

Additionally, in case each wireless sensor connects directly to a cloud server, more costs may occur: a cloud service monthly fee could make up an unexpectedly high total cost, considering the number of (hundreds of) sensor units in a building destination.

Fidelix centralized solution allows to collect hundreds of measurement series and transfer to cloud services at once, speeding up and reducing communication fees compared to separate sensors

Fidelix wireless M-Bus technology is simply cost-effective

One sensor contains several measurements at once, for instance, CO2, temperature, and humidity. In other words, for the price of one sensor device, you get the functions of more sensors.

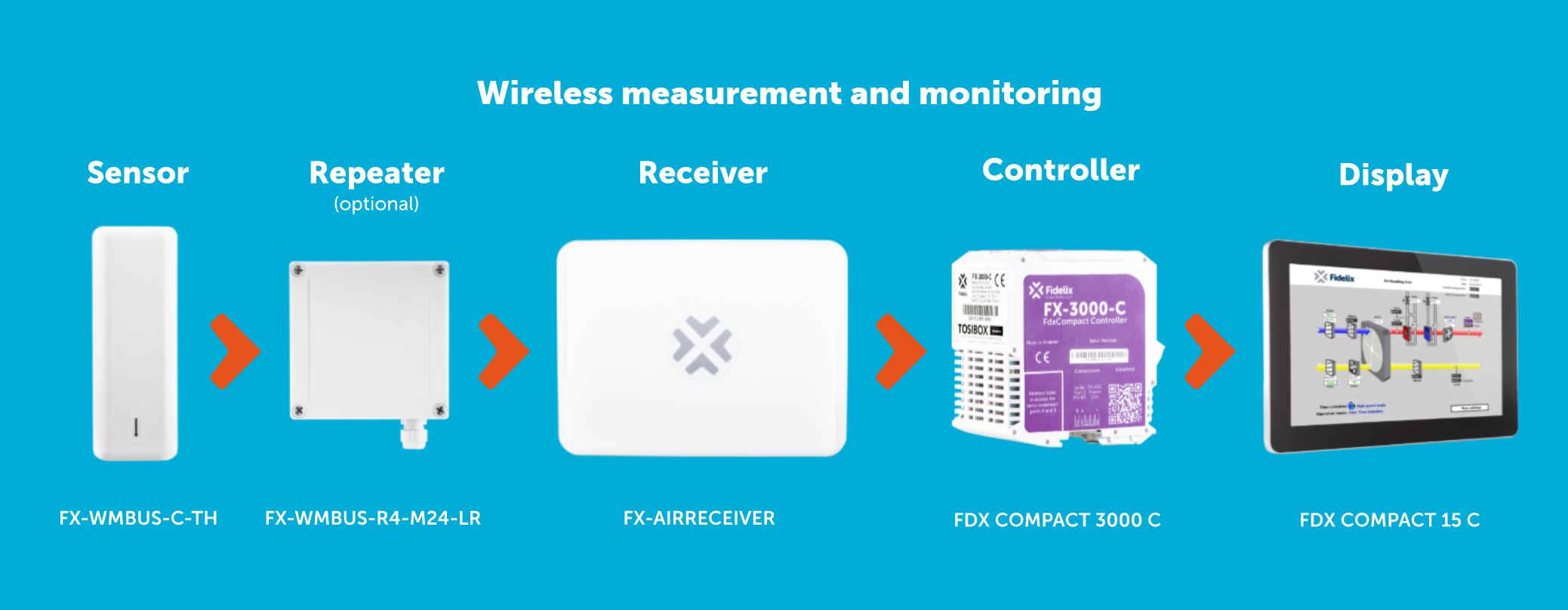

Instead of a cloud server, Fidelix wireless M-Bus sensor devices directly connect to an FX air receiver. FX air receiver compiles data, which it receives from hundreds of sensor devices, and re-directs it to a Fidelix FX-3000-C central unit. Or alternatively, if another brand device is in use, air receiver could also re-direct the data at once into a cloud server.

What comes to regular maintenance and repairs, cost saving plays an important role, too. The minimum battery lifetime of Fidelix wireless sensors is 10 years. For example, if wired sensor broke down, the repair and/or replacement could become quite a challenge both work- and cost-wise.

The only requirement for the above set-up is a local network that should be established between the FX-3000-C central unit and the FX air receiver.

Case: an apartment building

Let us think of a residential building with four sections that are each connected with a staircase.

- Each apartment unit would have, say, four (4) sensors measuring various qualities and quantities such as temperature, CO2, and humidity. There could be anything between 50 to 400 sensors in each building section.

- An FX air receiver would be installed into each staircase. That makes a total of four (4) air receivers

- An apartment building may have 1-3 technical rooms, and each one would have an FX-3000-C central unit that receives all data from air receivers

- Wiring (traditional 230VAC socket and LAN socket) may be needed only at the airReceiver (base station) and repeater installation places.

Solutions for enhancing signal propagation

Field tests and pilot projects show that concrete buildings in Finland are quite obstructive to the radio waves on wireless M-Bus band (868–869MHz).

The more steel and hard concrete there is in the building structures, the worse signal propagation becomes.

As a solution to this obstacle, Fidelix has several amplifying repeater model and antennas on offer.

A preliminary site visit and a signal propagation test may be needed to obtain a better understanding about the number of airReceivers, repeaters, and antennas needed. That will help drafting a budget, too.

Compatibility with other brands

Fidelix standard means that our devices communicate with all brands’ protocols: Open Metering System (OMS), Wireless M-BUS, and AES128 encryption, to mention some.

Whether you plan to renovate an old building automation or construct a brand-new building, Fidelix devices can form a part of the solution – together with your selection of other brand devices – or the entire solution. The latter ones include a complete Fidelix building automation system with sensors, I/O modules, receivers, central units and so on. You name it.

Pros of Fidelix Wireless M-Bus devices

Battery duration and lifespan

Sensors’ battery duration is 12-18 years. There’s no nuisance of constantly checking whether an individual sensor is out of battery. This makes the lifespan clearly long and user-friendly.

Coverage of signal

The reception of coverage of signal even in today’s dense building structures is excellent. The signal travel well through obstacles, that is various structure to the receivers.

Fidelix obtains a further selection of signal amplifiers, antennas and additional receivers on offer. Please find more about the products here

Would you like to learn more about the Fidelix Wireless M-Bus products and systems?

Please get in touch with us.

Asko Määttä, Head of Sales

+358 503 497 620

asko.maatta@fidelix.com

Azeem Mohammed, Partner Sales Manager

+358 509104382

Nikolai Zhukov, System Support Specialist